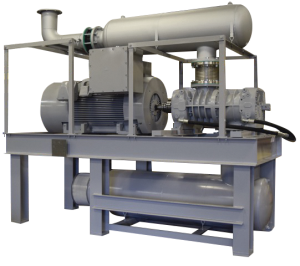

High Pressure Blower System Features Gardner Denver CycloBlower H.E.

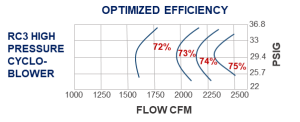

INOHVA and sister company, Universal Blower Pac, are proud to be one of the first to market with a cutting edge high pressure, high efficiency blower system that features Gardner Denver’s CycloBlower H.E. This system is able to handle operating pressures up to 36 PSIG and vacuum up to 22 Hg, making it ideal for numerous pneumatic conveying and industrial applications where heavy and dense materials are being conveyed. Our high pressure blower solution provides oil-free compressed air and eliminates the need for traditional and costly sliding vane and air compressor technologies. High efficiency, low maintenance, and lower upfront costs also make it an ideal solution for maximizing lifetime operating value.

HIGH PRESSURE. HIGH EFFICIENCY. LOW BOTTOM LINE.

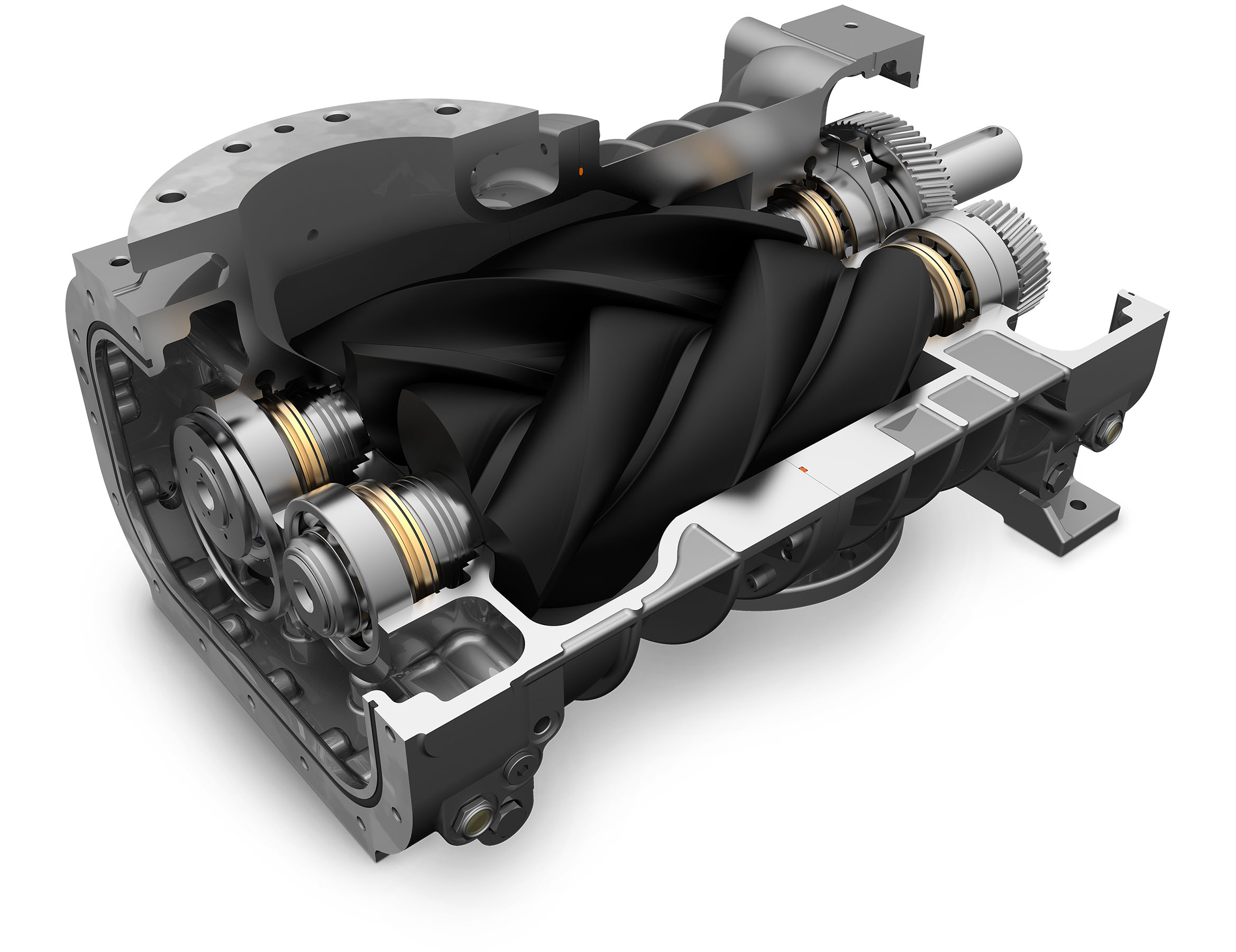

- The new CycloBlower H.E. Series features a game changing design patented design with best-in-class efficiency.

- Flexible options and installation supports various medium to high dense phase conveying with pressure ranges of 6-36 PSIG

- ONLY BARE rotary screw blower on the market available to retrofit existing systems, upgrade current system, or customize new improved system. Installation flexibility saves capital expense vs. inflexible, overpriced units.

- Oil-free compressed air saves on maintenance, runs cleaner without contaminating materials. Typical rotary vane/oil flooded screw compressors contaminate process materials to lubricative oils and aerosols, whereas our system avoids need for coalescing filters and complicated design/ upkeep. No wearing components, no-contact compression = No process air contamination.

- Patented 3 x 5 lobe helical screw rotor design features food grade PTFE coating to minimize air loss, maximize efficiency and produces market leading performance.

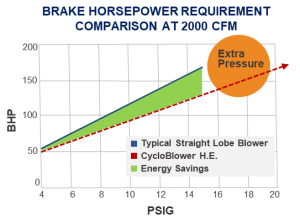

- Lower Horsepower = Lower Operating Costs. Lower energy consumption means lower bottom line, better ROI.

- Higher pressure system capabilities over typical straight lobe blower offer new conveying possibilities.

UBP’s CYCLOBLOWER H.E. SYSTEM COSTS 65% -75% OF SLIDING VANE SYSTEM. Additionally, lower horsepower and lower maintenance of our system provides significantly lower lifetime operating costs. This positive displacement and force fed lubrication system improves run conditions with less downtime. Controls and sensors protect your system – preventing excessive NPT. Lastly, PTFE (food grade Teflon) coated rotors minimize air loss and maximize system efficiency. Optimized discharge cylinders provide increased efficiency at low, medium and high pressures. Call us to evaluate how a customized high pressure system can work for your equipment and plant requirements.

No Comment