GD Cycloblower H.E. Series – Helical Screw – DSL

Airflow to 3,900 cfm | Pressure 36 PSIG | Vacuum 22 inHG

>> Best-in-class energy efficiency

>> Game-changing patented design

>> Built with best-of-the-best components

>> Flexible options & installation

GD Cycloblower – Helical Screw – DSL

Airflow 6,700 cfm | Pressure 20 PSIG | Vacuum 17 inHG | Wet Vacuum 24inHG

>> Efficiency leader at higher pressure

>> Quiet, shock-free compression

>> Clean air & gas delivery

>> Higher pressure & vacuum performance

GD Heliflow – Helical Tri-Lobe – DSL

Airflow 4,800 cfm | Pressure 15 PSIG | Vacuum 17 inHG

>> Innovative & revolutionary PB blower design

>> Reduced noise by 4-7 dBA

>> Superior overhung load capacity

GD TriFlow – Straight Tri-Lobe – DSL

Airflow 700 cfm | Vacuum 16 inHG

>> Designed for reduced noise and pulsation

>> Advanced oil/air seals for reliable air delivery

>> Heavy-duty design for reduced downtime

GD Cycloblower VHX

Airflow 764 cfm | Pressure 20 PSIG | Vacuum 18 inHG

>> Faster internal compression

>> Significantly larger discharge port

>> Eliminates air losses

GD RBS – Straight Tri-Lobe – DSL

Airflow 14,570 cfm | Pressure 15 PSIG | Vacuum 15 inHG

>> Tri-Lobe rotors offer quiet, efficient operation

>> Robust design for reliability and peace of mind

>> Optional flange mount for unsurpassed versatility

GD DuroFlow – Straight Lobe – DSL

Airflow 4,300 cfm | Pressure 15 PSIG | Vacuum 16 inHG

>> Designed for dusty, abrasive environments

>> Advanced oil/air seals for reliable air delivery

>> One piece rotor/shaft for increased durability

GD Sutorbilt – Straight Lobe – Grease & DSL

Airflow 4,300 cfm | Pressure 15 PSIG | Vacuum 16 inHG

>> Decades of proven results

>> Legend, 4500, 800 & Quiet Series

>> Available with mechanical seals

>> Most versatile blower available

F Series Centrifugal blowers for industrial use

Elmo Rietschle offers a broad portfolio of single and multistage centrifugal blowers for vacuum and pressure operation.

The applications of Radial blowers are mainly used in the packaging and paper industries, with the smaller units are suitable for extracting dust with fine material such as paper powder and powdered solids.

- Cast housing and impellers

- Robust and economical

- lubrication of bearings

- Quiet and vibration-free running

- Reliable and durable

- Speed control via frequency converter possible

G-Series – Side Channel Blowers Leading in Excellence

Some technologies are so good that it is hard to improve them. Side channel blowers from Elmo Rietschle are such an example. They have proven their reliability in service for many decades, performing flawlessly day in and day out with virtually no down time. Noise levels have been lower than that of most other vacuum pumps and compressors.

Side channel blowers are used for conveying gases and gas-air mixtures.

- Reliable and built-to-last, virtually maintenance-free

- Robust yet light-weight

- For use worldwide (UL/CSA/IEC/EN approval)

- 50/60 Hz voltage range motors

- ATEX 94/9 EG

- Adjustable speed via external or integral converter

L-Series – Compact Liquid Ring Pumps for Heavy Duty

Extreme conditions, which prevail in humid and wet processes, lead to lime scale or abrasion, and hence to a considerable reduction in the performance of the pump. Elmo Rietschle liquid ring pumps, however, meet these challenges.

The use of high-quality materials such as stainless steel and ceramics ensure utmost reliability and constant operating characteristics – for years to come.

- Constant operating characteristics by ceramic coating

- Maximum abrasion resistance

- Excellent corrosion resistance

- No deposits and lime scale

V-Series – Dry Running and Oil Lubricated Rotary Vane Pumps and Compressors

Elmo Rietschle offers dry running and oil lubricated rotary vane pumps which cover a wide performance range.

The eco-friendly dry running rotary vane pumps are used for vacuum, pressure and combined pressure and vacuum applications. The time-tested oil lubricated rotary vane machines are typically used for generating vacuum.

- Dry running and oil lubricated versions

- Low noise level

- Robust and economical

- Long up times

- Easy to operate

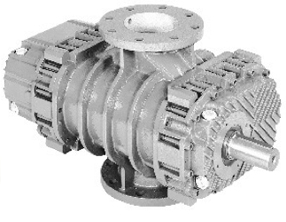

R-Series – Rotary Lobe Blowers: rugged and economical

These compact rotary lobe blowers belong to the group of dry running positive displacement pumps. This means that there is no need for oil or grease in the compression chamber. Only gear box and bearings, which are separated from the pumping chamber, are oil lubricated. Two non contacting triple lobed rotary lobe rotors rotate against each other in the compression room.

The triple lobed rotors avoid pulsation problems. The blowers are customized to cater for the varying demands of our customers‘ applications.

- Robust and economical

- Dry running

- Modular design

- Available as single aggregates

- Available as individually engineered pump sets

- Frequency control available

C-Series – Innovative Claw Technology

The C-Series claw pumps and compressors of Elmo Rietschle generate contact-free vacuum or compressed air efficiently and economically. This is possible because of the principle of internal compression. The gas is pre-compressed within the compressing chamber and is then discharged.

This leads to an evident energy saving compared to rotary lobe blower designs without internal compression.

- Dry, contact-free operation

- Process safe and reliable

- No oil in the compression chamber

- Frequency control available

- Low sound level

- No greasing of bearings

S-Series – The Screw: dry running and low maintenance vacuum pump

The S-VSI screw vacuum pump (sizes 100 and 300) represents modern, state-of-the-art dry running technology that excels when it comes to small carbon footprint and low life cycle costs. It is used in a variety of industrial applications such as drying and packaging. Click here to find out more.

The S-VSA and S-VSB dry running, contact-free screw vacuum pumps are primarily used in the chemical and pharmaceutical industries for processing applications. A contamination with oil or other operating liquids is impossible. Several pump sizes are available with ATEX certification.

- Dry running

- High vacuum in one stage

- Application specific options

- Short evacuation time due to high suction capacities

- Insensitive against water shocks